Type CLZ axial-flow fans for marine use (vertical type), or simply type CLZ fans, are designed primarily for ventilation of the machinery room and each compartment. The construction can be delivered for air supply or air exhaust, the ocean air containi

1. CONTRUCTION

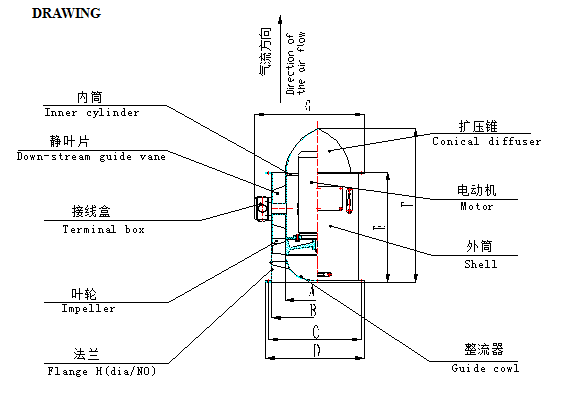

1.1Type CLZ fan consists of the impeller, Casing, motor, guide cowl, conical diffuser, etc.

1.2Casing is made of steel plate of having ample thickness, being composed of an inner cylinder, a shell and a down-stream guide vane. The shell is made in the shape of a cylindrical duct with flanges for connection of ducts at both ends. The inner cylinder and the shell is connected with the downstream guide vane used to guide the air flow.

1.3Motor-Built-in Motor type(to be mounted on the inner cylinder) which is manufactured by the motor factory is specially designed to suit CLZ fan contraction, it is totally enclosed, natural cooled, and it is capable of standing salt spray, vibration or shocking. There are two types: ZZT-H Series DC marine motor (rated voltage 220V) and Y-H series AC marine motor (rated voltage 220/380V).

1.4Propeller is made of carrion resistant aluminum alloy (cast), being carefully balanced and mounted directly on the motor shaft extension.

1.5The guide cowl installed on the inlet and the conical diffuser installed on the outlet are used to cut the vortex of the air flow, to ensure higher efficiency of the fan. Material: enforced plastics.

1.6Finish-The fan are either printed and painted with marine paint.

2. APPLICATION

In the other case sand actual speed is different from the parameters shown in the table, the specific property of CLZ fan can be calculated by the following formulae:

Capacity: Q=Q0·![]() ( m3/h )

( m3/h )

Pressure: P=P0·(![]() )2·

)2·![]() ( Pa )

( Pa )

Power: N=N0·(![]() )3·

)3·![]() ( KW )

( KW )

Where: Q0 、P0 、N0、、n0 are the standard parameters shown in the table and Q 、P、N、 、n are the actual parameters, symbolizing capacity, pressure, power, air density and speed separately.

3.PROPERTY PARAMETERS TABLE

NO. | Type Form | Capacity m³/h | Total pressure Pa | Speed r/min | Shaft Power (KW) | Motor | |

Type | Power | ||||||

1 | CLZ1— | 1600 | 200 | 2900 | 0.142 | ZZT2/30-H | 0.2 |

Y632-2-H | 0.25 | ||||||

2 | CLZ2- | 1600 | 350 | 2900 | 0.219 | ZZT4/30-H | 0.4 |

Y712-2-H | 0.55 | ||||||

3 | CLZ3- | 2500 | 300 | 2900 | 0.292 | ZZT4/30-H | 0.4 |

Y712-2-H | 0.55 | ||||||

4 | CLZ4- | 2500 | 500 | 2900 | 0.512 | ZZT8/30-H | 0.8 |

Y801-2-H | 0.75 | ||||||

5 | CLZ5- | 4000 | 400 | 2900 | 0.63 | ZZT8/30-H | 0.8 |

Y801-2-H | 0.75 | ||||||

6 | CLZ6- | 4000 | 700 | 2900 | 1.12 | ZZT15/30-H | 1.5 |

Y90S-2-H | 1.5 | ||||||

7 | CLZ7- | 6000 | 750 | 2900 | 1.53 | ZZT22/30-H | 2.2 |

Y90L-2-H | 2.2 | ||||||

8 | CLZ8- | 9000 | 800 | 2900 | 2.6 | ZZT30/30-H | 3 |

Y100L-2-H | 3 | ||||||

9 | CLZ9- | 12000 | 500 | 1450 | 2.1 | ZZT30/15-H | 3 |

Y100L2-4-H | 3 | ||||||

10 | CLZ10- | 12000 | 900 | 1450 | 3.8 | ZZT55/15-H | 5.5 |

Y132S-4-H | 5.5 | ||||||

11 | CLZ11- | 16000 | 500 | 1450 | 3.3 | ZZT40/15-H | 4 |

Y112M-4-H | 4 | ||||||

12 | CLZ12- | 16000 | 1100 | 1450 | 6.0 | ZZT75/15-H | 7.5 |

Y132M-4-H | 7.5 | ||||||

13 | CLZ13- | 25000 | 600 | 1450 | 5.2 | ZZT75/15-H | 7.5 |

Y132M-4-H | 7.5 | ||||||

14 | CLZ14- | 25000 | 1100 | 1450 | 10.2 | ZZT130/15-H | 13 |

Y160L-4-H | 15 | ||||||

Remarks: The performance parameters shown in the table are based on the air conditions of absolute 101325Pa, temperature 20℃, relative humidity 50%, specific gravity 1.2kg/m³, and standard speed shown in the table.

4.Outline Dimensions of vertical type Axial-flow fans for marine use

型 号 Type Form | 电动机型号 Type Motor

| A φ | B φ | C φ | D φ | E | F | G | 12- φ | WT.Kg |

CLZ1- | ZZT2/30-H | 162 | 280 | 320 | 350 | 360 250 | 587 410 | 427 377 | φ9 | 45 28 |

Y632-2-H | ||||||||||

CLZ2- | ZZT4/30-H | 180 | 260 | 305 | 380 | 430 280 | 606 445 | 407 357 | φ9 | 52 32 |

Y712-2-H | ||||||||||

CLZ3- | ZZT4/30-H | 162 | 320 | 360 | 390 | 430 280 | 606 445 | 467 417 | φ9 | 58 37 |

Y712-2-H | ||||||||||

CLZ4- | ZZT8/30-H | 195 | 320 | 360 | 390 | 500 330 | 726 510 | 465 460 | φ9 | 78 51 |

Y801-2-H | ||||||||||

CLZ5- | ZZT8/30-H | 195 | 350 | 390 | 420 | 510 330 | 736 512 | 495 475 | φ9 | 83 53 |

Y801-2-H | ||||||||||

CLZ6- | ZZT15/30-H | 280 | 420 | 460 | 490 | 560 360 | 880 680 | 570 545 | φ9 | 144 77 |

Y90S-2-H | ||||||||||

CLZ7- | ZZT22/30-H | 280 | 440 | 480 | 510 | 600 400 | 920 700 | 590 570 | φ9 | 88 84 |

Y90L-2-H | ||||||||||

CLZ8- | ZZT30/30-H | 280 | 500 | 560 | 590 | 620 400 | 940 700 | 660 640 | φ11 | 182 109 |

Y100L-2-H | ||||||||||

CLZ9- | ZZT30/15-H | 410 | 640 | 700 | 732 | 740 500 | 1260 955 | 801 776 | φ11 | 312 170 |

Y100L2-4-H | ||||||||||

CLZ10- | ZZT55/15-H | 410 | 640 | 700 | 732 | 1166 1020 | 1633 1480 | 801 776 | φ11 | 474 318 |

Y132S-4-H | ||||||||||

CLZ11- | ZZT40/15-H | 410 | 700 | 760 | 792 | 765 500 | 1285 965 | 861 833 | φ11 | 358 190 |

Y112M-4-H | ||||||||||

CLZ12- | ZZT75/15-H | 410 | 700 | 760 | 792 | 1198 1020 | 1665 1480 | 861 833 | φ11 | 524 465 |

Y132M-4-H | ||||||||||

CLZ13- | ZZT75/15-H | 440 | 780 | 836 | 870 | 810 530 | 1375 1045 | 940 930 | φ11 | 417 465 |

Y132M-4-H | ||||||||||

CLZ14- | ZZT130/15-H | 440 | 780 | 836 | 870 | 1406 1090 | 1916 1605 | 940 930 | φ11 | 460 495 |

Y160L-4-H |

Remark: weight ( WT ) shown in the table including fan and motor.

5. Introduction for ordering

5.1 Please introduce the model, flow prate, pressure, speed and structure of fan、50HZ or 60HZ.

5.2 If the fan on the deck, according to relevant provisions of the chassis thickness.

5.3 Please offer insulation class and protection class for fan motor (if not, the insulation class is B, protection class is IP44).

5.4Our factory can offer the fans of special specification and usage according to the user's demands.

5.5We are responsible for the repair, exchange and return of the products Within 18 months.

6. Use and maintenance

6.1 Before installing the fans, should check whether each part is intact, whether the components are complete, whether the impeller and casing rotating direct are concordant.

6.2When installing the duct of the inlet and outlet, should make the duct and fans be spontaneous identical, not join them forcing, not bring the weight of duct on the fans.

6.3After installed the fans, check whether there is friction of collide between the impeller and the fixed parts by rotating the impeller. If collision, friction, loud noise or strong vibration happened, the fan should be restart after checking. Avoid the fan being bumped and other substance or liquid entered the fans. Please clean the dust on blade of impeller in time, so as not to break the balance and strengthen the noise.

6.4The fans should be started-up while the inlet is opening,

6.5After the fans wiring, the terminal box should be sealed, avoid the air or water in it.

6.6As the fans operating, the motor electric current should be control strictly, not exceed the rated electric current. Avoid the motor burning,

6.7The fans maintain must be done on stop working time. When burning, after check, should whether the every part of fans is normal.

6.8As some fault occurred in fans operating, should find out the reason in time and think a way of resolution.