CQ series marine centrifugal ventilators or simply the ventilator is capable of blowing air, ocean air containing salt vapour, and corrosive air which contains oil vapour and a small quantity of acid steam generated by the natural evaporation of the

1. WORKING CONDITIONS

Medium temperature: -25℃ ~ +50℃

Max relative humidity: 95%

Periodical swing: ±22.5°

Continued transversal incline: ±15°

Continued longitudinal incline:±10°

Vibration: existent

Impact: existent

2. CHARACTERISTICS

Small size and light weight.

Low-noise ,low vibration.

Good anti-corrosiveness.

Good air tightness.

Small starting torque.

Strong resistance against swing, vibration and impact.

3. STRUCTURE TYPE

The ventilator is designed and manufactured into a horizontal structure type or a vertical one, which the vane wheel is mounted directly on the motor shaft extension.

The vane wheel, being riveting structure is made of aluminum alloy and carefully balanced by static and dynamic ways.

Both the machine casing and the inlet are made of welded common steel .

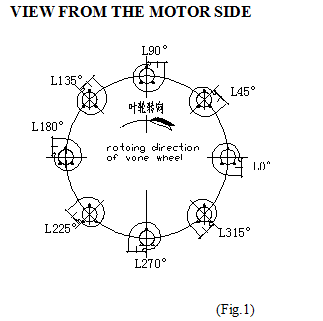

The ventilator can be made for left or right rotation:

Left rotation-viewed from the motor side, the vane wheel rotates clock-wise and indicated as “L”.

Right rotation-viewed from the motor side, the vane wheel rotates clockwise and indicated as “R”.

The outlet position of ventilator, according to the rotating direction of vane wheel, is made into the following main types. In conformity with the requirement, the outlet position is allowed to use other types, the step angle of which is 30°or 22.5°.

The ventilator can be matched with marine AC motor of 380V.50HZ or marine motor DC 220V.

4. Use and maintenance

4.1 Before installing the fans, should check whether each part is intact, whether the components are complete, whether the impeller and casing rotating direct are concordant.

4.2 The air enter the fan from axial direction and come out through the impeller. It can be used for left or right rotation.

4.3 When installing the duct of the inlet and should make the duct and fans be spontaneous

outlet, identical, not join them forcing, not bring the weight of duct on the fans.

4.4 After installed the fans, check whether there is friction of collide between the impeller and the fixed parts by rotating the impeller. If collision, friction, loud noise or strong vibration happened, the fan should be restart after checking. Avoid the fan being bumped and other substance or liquid entered the fans. Please clean the dust on blade of impeller in time, so as not to break the balance and

strengthen the noise.

4.5 The fans should be start-up without load. Before the fans started, should close the inlet orthe adjust fittings. After operating, start to turn on it until to the formulary work state.

4.6 The impeller’s rotating direct and the direct of the arrow should be concordant.

4.7 After the fans wiring, the terminal box should be sealed, avoid the air or water in it.

4.8 As the fans operating, the motor electric current should be control strictly, not exceed the rated electric current. Avoid the motor burning,

4.9 The fans maintain must be done on stop working time. When burning, after check, should whether the every part of fans is normal.

4.10 As some fault occurred in fans operating, should find out the reason in time and think a way of resolution.

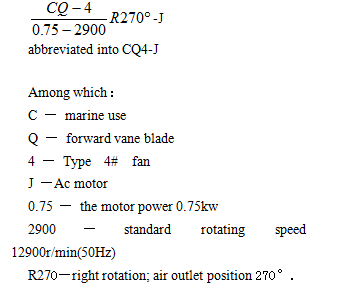

5. MODEL EXPLANATION

The model of ventilator is indicated with the first letter of the Chinese phonetic name, the vane wheel diameter and the standard speed etc.

For example: