Preface

CBL series explosion-proof axial centrifugal fans for marine use are designed and manufactured according to GB 11799-89(Marine Explosion-proof Axial Centrifugal Fans), and general description and explosion-proof electrical equipment “d” of

1. Application

They can be delivered for gas mixtures or vapour containing combustibles and explosives, for ordinary air, for sea air containing salt fog, for air containing oil fog and other corrupt air supply or extracition.

Theses explosion-proof fan series are best suited to pumping out gas mixtures or vapour containing combustibles and explosives in oil cabins holds, pump-rooms, battery cabins, ammunition cabins, hangars, paint houses, etc . They can also be used for ventilation of other compartments of shipping and corresponding place of land's.

AC 50HZ, 380V or 60HZ,440V type YB-H (

Explosion-insular) or type Y-H (ordinary) three-phase asynchronous motors for marine use may be mounted on these fans

2. Operation Conditions

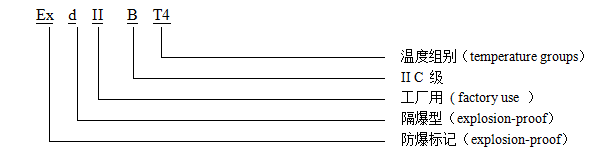

For places where there are explosive gas

mixtures of grade

Ambient temperatures: -25℃ ~ +50℃

Relative humidity of the air: ≤95%

Cyclical vacillation: 22.5°~ 45°

Sustained horizontal tilting: ±15°

Sustained vertical tilting: ±10°

Vibration: existent

Shock: existent

3. Structural Types

There are two structural types: type I (motor-direct-driving type), type II (Separate cabins type).The construction is spark free.

The structure of type I is a motor-direct driving one, the vane wheel is mounted directly to motor-shaft, and the housing is fixed on the flange of the explosion-proof motor.

The type II is a separate structure, i.e. the fan and the motor are put into different cabins, with a driving device, a pairs of flexible coupling, and the driving device consists of bearings, bearing-box, shaft, brass rings, stuffing, it can be oiled and measured temperature, one side is fixed on the fan, and the other side will be mounted on the bulkhead.

The fan may be made into a horizontal or vertical, single-stage, single-drawing and airtight structure by the customer’s requesting.

The fan can be made into a counter clock-wise rotating type or a clockwise one.

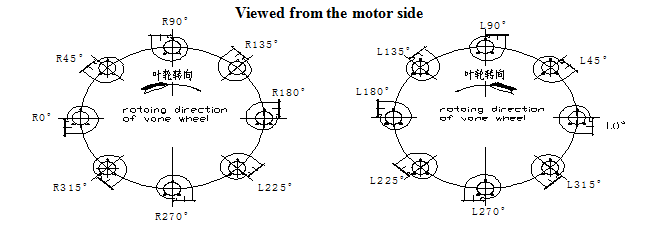

The counter-clockwise rotating type (Left turning type)-Taking a front view from the motor side, you will see the vane wheel turns counter-clockwise. We use “L” to indicate it, and by the same way, the clockwise rotating type can be indicated as “R”.

The outlet position of the fan, according to the rotating direction of the vane wheel, is made into the following main types, by your requesting the outlet position is allowed to use other types, the angle of which is 30°or 22.5°

4.Features

Explosion-proof、safe and reliable in operation.

Small in size, light in weight, and low in noise.

Well anticorrosive.

Strongly capable of resisting vacillation、vibration and shocking.

5.Type Explanation

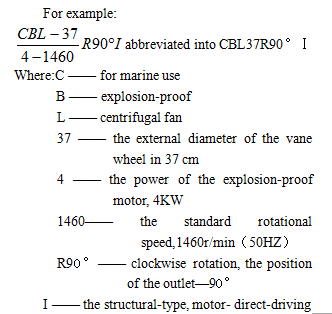

The type of explosion-proof fans are expressed

by the first letter of the Chinese phonetic name, the outer diameter of the vane wheel, the standard speed, and the power of the attached explosion-proof motor, etc.

6. Gradingang Groupiong of Dangerous Explosives Mixtures (Table I)

Dangerous explosive mixture are graded according to their ability of spreading explosion, they are grouped according to their ignition temperatures.

组别groups 级别grades | T1 (420℃<t) | T2 (300℃<t≤450℃) | T3 (200℃<t≤300℃) | T4 (135℃<t≤200℃) |

IIA | 甲 烷 Methane 乙 烷 Ethane 丙 烷 Propane 甲 苯 Toluene 醋 酸 Acetic acid 一氧化碳 Carbon monoxide 苯 Benzene | 甲酸乙脂 Ethyl acetate 甲 醇 Methanol 乙 醇 Ethanol 乙 苯 Ethylenzene 二氧乙烷 dichloroethane | 石 油 Petroleum 车用汽油 Gasoline 燃 料 油 Fuel oil 煤 油 Diesel oil 柴 油 Diesel oil 松 节 油 turpentine | 乙 醛 Acetaldehyde 三 甲 醛 Trmethylamine

|

IIB | 焦炉煤气 Gas from coking coal 氰 化 氢 Cyan hydrogen 环 丙 烷 Naphthene 丙 炔 alkynes | 环氧乙炔 Epoxyethane 乙 烯 Ethylene 丙乙酸甲酯 acrylics | 硫 化 氢 Vulcanized oxygen 四氢呋喃 Tetrahydrofuran 二 甲 醚 ether | 四氟乙烯 Fluan 二 乙 醚 Diether 乙基甲基醚 Ethyl ether |

IIC | 氢 Hydrogen 水 煤 气 Water gas | 乙 炔 Acetylene cthyme |

7. Application

The performance parameters shown in table 2 are based on the air conditions of absolute pressure 101325 Pa, temperature +20℃, relative humidity 50%, and density

1.2kg/ m3. That is: standard air conditions.

In the case of other air conditions and rotator speed different from table 2, the performance of the explosion-proof fan can be computed according to the following formulas:

Q=Q0·![]() ( m3/h )

( m3/h )

P=P0·(![]() )2·

)2·![]() ( Pa )

( Pa )

N=N0·(![]() )3·

)3·![]() ( KW )

( KW )

Where Q0 , P0 , N0, ![]() ,

,

n are respectively the flow rate, the pressure, the power and the air density under the standard air conditions and the standard speed n0; Q, P, N, ρand n are the actual flow rate, pressure, power, air density and speed separately.

8. Notes to purchasers

8.1. When ordering our products, please inform us the following details: the size number, structural type, flow rate, pressure, speed, rotating direction, the outlet position of the fn; the type and power of the motor, etc.

8.2. Supply of the machine as a complete set includes an explosion-proof fan fixed together (including an explosion-proof motor).

8.3. Please give us your detail information when you need a grade IIC explosion-proof fan or other special need.

8.4 By your request, the following items may be supplied to and please include them with your order:①vane wheel,②dismounting tool for vane wheel,③casing,④driving device,⑤coupling etc.

9. Use and maintenance

9.1 Before installing the fans, should check whether each part is intact, whether the components are complete, whether the impeller and casing rotating direct are concordant.

9.2The air enter the fan from axial direction and come out through the impeller. It can be used for left or right rotation.

9.3When installing the duct of the inlet and outlet, should make the duct and fans be spontaneous identical, not join them forcing, not bring the weight of duct on the fans.

9.4After installed the fans, check whether there is friction of collide between the impeller and the fixed parts by rotating the impeller. If collision, friction, loud noise or strong vibration happened, the fan should be restart after checking. Avoid the fan being bumped and other substance or liquid entered the fans. Please clean the dust on blade of impeller in time, so as not to break the balance and strengthen the noise.

9.5The fans should be start-up without load. Before the fans started, should close the inlet or the adjust fittings. After operating, start to turn on it until to the formulary work state.

9.6The impeller’s rotating direct and the direct of the arrow should be concordant.

9.7After the fans wiring, the terminal box should be sealed, avoid the air or water in it.

9.8As the fans operating, the motor electric current should be control strictly, not exceed the rated electric current. Avoid the motor burning,

9.9The fans maintain must be done on stop working time. When burning, after check, should whether the every part of fans is normal.

9.10As some fault occurred in fans operating, should find out the reason in time and think a way of resolution.

10. Precaution

10.1. The hard particulate matter in the combustible and explosive gas mixture is mot allowed to be more than 150mg/m3, and its maximum diameter cannot exceed to 2 mm.

10.2. On the duct intake side, provide a protective brass wire nets to ensure the prevention of foreign matter and electrostatic sparks from invasion, protection class of outlet to not less than IP10, so as to insure the explosion-proof fan operating safely.

10.3. When a power cable is inserted in the terminal box and fixed there, the terminal box itself and its approaching device must be sealed tightly with the cable, and no permeation of rain water into the terminal box is allowable,

10.4. Be sure to earth the cable, especially the flameproof motor.

10.5. Explosion-proof fan installation should be carried out with much care in connecting with the duct so as not to allow any casing distortion to take place owing to forceful tightening,

Our products can be exchanged, returned and repaired if found its quality unsatisfactory within 18 months from the date of factory.